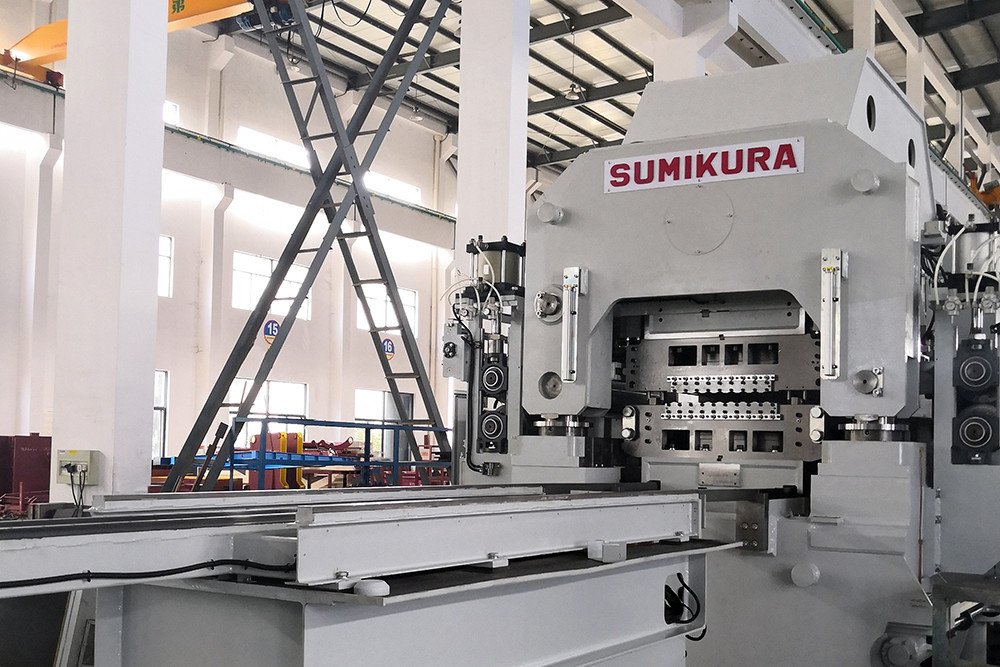

The automatic precision cut-to-length line is a modern metal processing system designed to convert coiled steel and aluminum into accurate flat sheets. With full automation, high output, and advanced control technology, this equipment streamlines coil handling, straightening, measuring, shearing, and stacking into a continuous workflow. By eliminating unnecessary manual handling, the machine greatly enhances production efficiency and sheet accuracy, making it a vital tool in large-scale manufacturing industries.

At its core, the machine’s function is to transform large coils into sheets of customized dimensions that are ready for downstream manufacturing processes. The system begins with automated coil loading, followed by leveling to remove coil set and surface stress, ensuring flatness across the sheet. Once the desired length is set, the shear unit cuts the sheets with precision, after which they are neatly stacked for easy handling. These sheets are widely used in industries such as automotive manufacturing, ship construction, electrical appliances, metal furniture, and building materials, where high consistency and exact sheet size are crucial. The cut-to-length line not only increases production speed but also reduces waste, ensuring cost savings and better utilization of raw materials.

The automatic cut-to-length line combines strength, versatility, and intelligent control. It accommodates coils up to 35 tons, making it suitable for heavy-duty industrial applications. With a working width capacity of 2,500 mm and sheet lengths up to 12,000 mm, the machine meets the needs of both small precision parts and oversized sheet production. Its thickness range of 0.2 mm to 9.0 mm covers everything from thin aluminum sheets to robust hot-rolled steel plates. The system operates at adjustable speeds of up to 80 meters per minute, with shear options including both stop shear for thick materials and rotary shear for high-speed, thin-sheet processing. Additionally, the integrated leveling system ensures optimal flatness, while advanced control software allows quick setup and changeovers, making the line adaptable to diverse production demands.

Material Handling: HSS, CRS, HRS, Stainless Steel, Aluminum

Max Coil Weight: 35 tons

Width Capacity: 2,500 mm

Length Capacity: 12,000 mm

Thickness Range: 0.2 mm – 9.0 mm

Processing Speed: 0–80 m/min

Shear Type: Stop Shear / Rotary Shear

Automation: Fully automatic coil loading, leveling, measuring, cutting, and stacking

These specifications make the equipment highly flexible and capable of serving different material grades and sheet dimensions while ensuring accuracy and consistency in every cut.

To operate the line efficiently, the coil should be loaded onto the decoiler with proper centering and safety checks. Once threaded into the leveling unit, operators must set the sheet length, thickness, and cutting parameters via the control panel. The automated system will then process the coil continuously, measuring and cutting sheets with precision. Operators should monitor the straightening performance, cutting accuracy, and stacking alignment during operation. Routine inspections of the shear blades, leveling rollers, and lubrication system are required to maintain stable performance. Safety protocols must always be followed, including lockout procedures during maintenance and correct use of protective equipment.

Your cutting line specialists!

Factory in Japan

Factory in Japan

ADDRESS

487-3, Sanshincho, Chuoku, Hamamatsu, Shizuoka, Japan

Japan local market : +81 53-425-5331

Japan local market : +81 53-425-5331

Factory in China

Factory in China

ADDRESS

265 Yixian Road, Deqing, Zhejiang, China

Overseas market : +86 572-883-2016

Overseas market : +86 572-883-2016