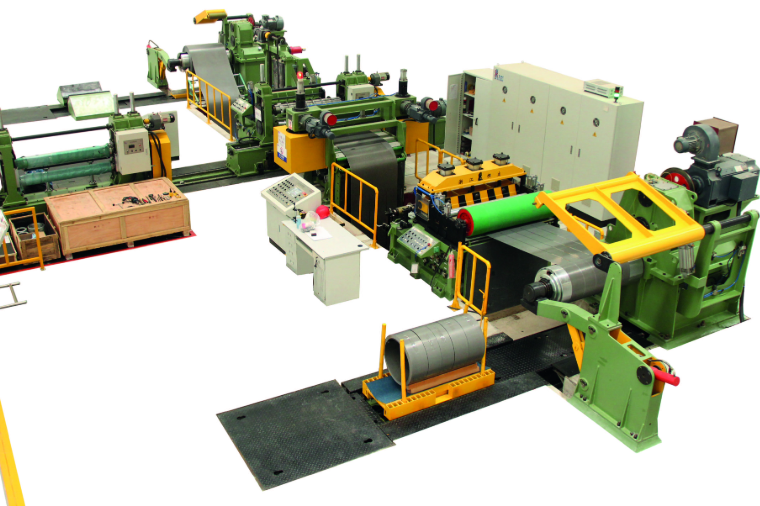

A Transformer steel slitting machine is a specialized piece of equipment designed to cut large steel coils into narrower strips with high precision, making it indispensable in transformer manufacturing and other electrical industries. The machine excels in processing various types of electrical steel, including cold-rolled and grain-oriented steel, which are essential for transformer cores due to their low iron loss and high magnetic permeability. Its primary function is to ensure that steel strips are cut accurately to the required width, maintaining consistent thickness and edge quality. Beyond transformers, these machines are also used in electrical motors, inductors, and other components that demand high-quality steel laminations. By automating the slitting process, it significantly reduces manual labor, minimizes material waste, and improves production efficiency in high-volume manufacturing environments.

Transformer steel slitting machines are built with advanced technology to provide precision, durability, and user-friendly operation. One key feature is the adjustable slitting mechanism, which allows operators to customize the width of the steel strips according to production requirements. The machine often incorporates a high-precision leveling system to eliminate coil tension issues, ensuring smooth and uniform slitting. Safety features such as automatic stop systems, protective covers, and emergency brakes are standard, enhancing workplace safety. Furthermore, modern models are equipped with digital controls and touch-screen interfaces, enabling operators to monitor cutting speed, coil tension, and blade condition in real time. Some machines include automatic coil loading and unloading systems, reducing downtime and labor costs. Noise reduction technologies and vibration-damping structures are also commonly applied to improve the working environment.

Operating a Transformer steel slitting machine requires careful attention to setup and maintenance. First, the operator must properly align the steel coil on the unwinding station and adjust the tension to avoid stretching or wrinkling. Blade settings must be calibrated according to the desired strip width, and the machine should undergo a test run to verify precision before full-scale production begins. Regular maintenance is crucial, including lubrication of moving parts, inspection of blades for wear, and cleaning of the cutting area to prevent accumulation of debris. Operators should also monitor the machine’s control panel to detect any abnormal vibration or overload conditions. Proper training in safety procedures and handling of electrical steel is essential to prevent accidents and ensure consistent product quality.

Your cutting line specialists!

Factory in Japan

Factory in Japan

ADDRESS

487-3, Sanshincho, Chuoku, Hamamatsu, Shizuoka, Japan

Japan local market : +81 53-425-5331

Japan local market : +81 53-425-5331

Factory in China

Factory in China

ADDRESS

265 Yixian Road, Deqing, Zhejiang, China

Overseas market : +86 572-883-2016

Overseas market : +86 572-883-2016