Automobile sheet blanking lines are essential equipment in modern automotive manufacturing, designed to transform raw metal coils into precise, ready-to-use blanks for car body panels, structural components, and other automotive parts. Utilizing cold-rolled steel (CRS) and hot-rolled steel (HRS), these lines allow manufacturers to achieve high-quality blanks with minimal waste. The primary function of this system is to provide an automated, continuous process that cuts sheets to exact dimensions, ensuring consistency across large production volumes and reducing manual handling errors. These lines are particularly suited for the high demands of automotive assembly lines, where accuracy, speed, and reliability are paramount.

Automobile sheet blanking lines boast several advanced features designed to optimize production. The system is equipped with a robust hydraulic press capable of exerting up to 800 tons of force, accommodating sheet sizes up to 5,000 × 2,750 mm. It can handle materials with a thickness ranging from 0.2 mm to 2.5 mm, covering most automotive panel requirements. The line operates at a speed of up to 65 strokes per minute (SPM), ensuring high throughput without compromising accuracy. Additionally, the magnetic stacking system automatically organizes the finished blanks, reducing labor costs and minimizing damage during stacking. With advanced control systems and safety mechanisms, operators can manage the process efficiently while maintaining workplace safety standards.

The automobile sheet blanking line is engineered to handle a wide range of metal dimensions and types. The machine can process sheet widths from 300 mm to 2,000 mm and lengths from 300 mm to 6,000 mm, making it adaptable for various automotive components. Its hydraulic press provides precise cutting, ensuring consistent blank sizes that meet tight tolerance requirements. The magnetic stacking system is designed to lift and arrange sheets uniformly, preventing scratches and deformations that can affect downstream forming processes. These specifications make the line suitable for both small-scale production and high-volume automotive manufacturing, providing flexibility for different operational needs.

While primarily designed for the automotive sector, sheet blanking lines are versatile and can be used in various industries requiring precision metal cutting. This includes household appliance manufacturing, construction materials, metal furniture production, and other industries that demand uniform, high-quality sheet blanks. By integrating this equipment, manufacturers can improve production efficiency, reduce material waste, and maintain consistent product quality, supporting both cost savings and competitive advantages in the market.

Your cutting line specialists!

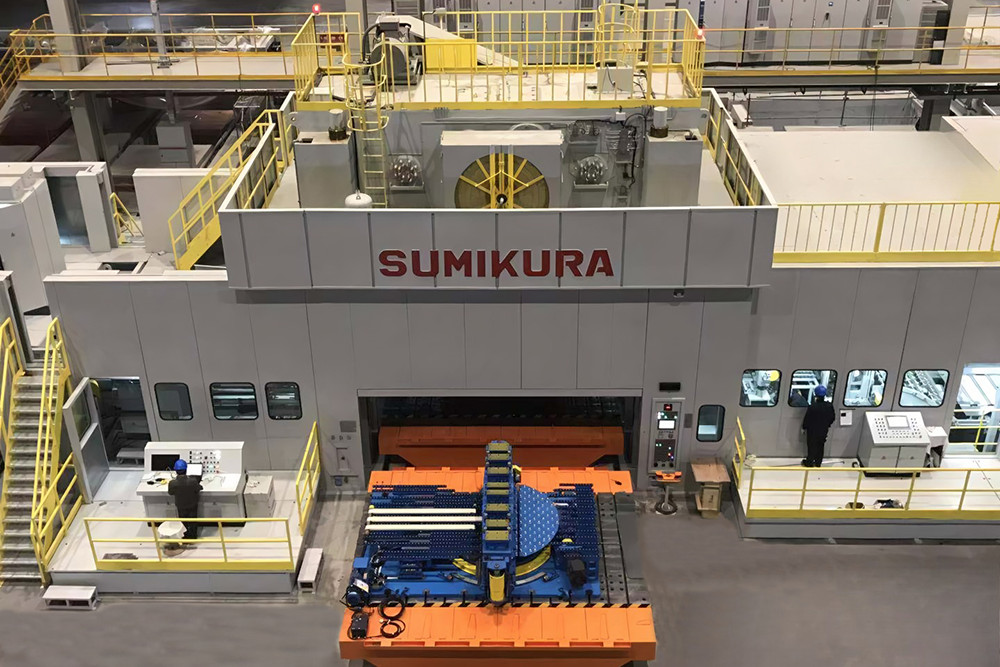

Factory in Japan

Factory in Japan

ADDRESS

487-3, Sanshincho, Chuoku, Hamamatsu, Shizuoka, Japan

Japan local market : +81 53-425-5331

Japan local market : +81 53-425-5331

Factory in China

Factory in China

ADDRESS

265 Yixian Road, Deqing, Zhejiang, China

Overseas market : +86 572-883-2016

Overseas market : +86 572-883-2016