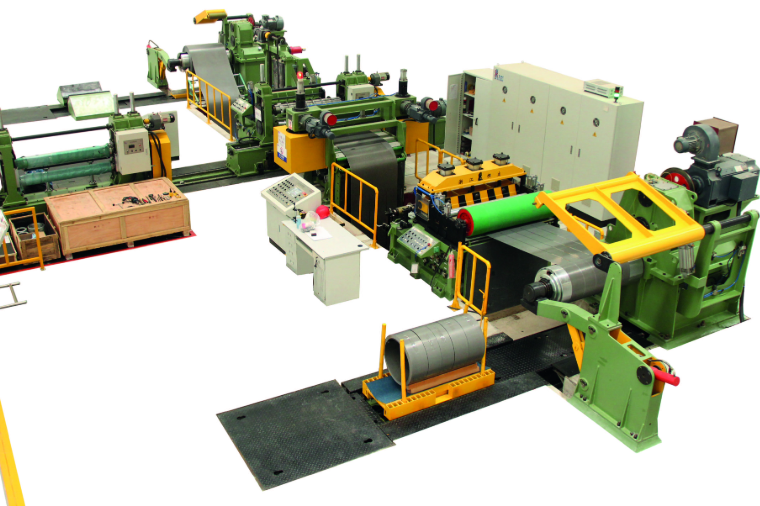

Automation silicon steel slitting lines are advanced systems designed specifically for processing silicon steel coils with high efficiency and precision. Silicon steel, widely used in transformers, motors, and electrical equipment, requires exacting tolerances and clean-cut edges to maintain its magnetic properties. Automation in the slitting process ensures minimal handling errors, consistent quality, and rapid throughput, making it an essential investment for manufacturers producing electrical-grade steel components. By integrating cutting-edge control systems, precision slitting heads, and automated coil handling, these lines provide unmatched performance in processing delicate, high-value materials.

The primary function of an automation silicon steel slitting line is to convert wide silicon steel coils into narrower strips with precise widths and high-quality edges. The system is equipped with advanced circular slitting knives, tension control units, and automatic recoilers to ensure that each strip maintains the material’s integrity without burrs, scratches, or deformation. These lines are capable of handling both non-oriented and grain-oriented silicon steel, making them suitable for producing strips for transformers, motors, magnetic cores, and electrical laminations. The automation features, including programmable slitting widths and tension adjustments, allow manufacturers to switch between different coil sizes and grades rapidly, enhancing production flexibility and efficiency.

Automation silicon steel slitting lines are designed for high-speed, continuous operation while maintaining precise control over coil tension and edge quality. The system’s structure is reinforced to reduce vibration and mechanical stress, which is critical when processing thin or high-grade silicon steel. Servo-driven recoilers and pay-off units ensure consistent tension throughout the coil’s length, preventing stretching or wrinkling. The slitting head is equipped with multiple knives that can be adjusted individually, allowing for narrow or wide slitting as required. Additionally, the line includes real-time monitoring and diagnostics, enabling operators to detect and correct deviations instantly, thus minimizing material waste and maintaining consistent product quality.

A typical automation silicon steel slitting line can accommodate coil widths of up to 1350 mm and coil weights ranging to15 tons. The material thickness range is usually 0.15–0.5 mm for high-grade transformer steel, though some lines can handle slightly thicker or thinner coils. Processing speeds often reach 150-300 meters per minute, depending on coil width, thickness, and material grade. The slitting knives are made of high-speed steel or alloy steel, ensuring long service life even under continuous operation. The line also features high-capacity recoilers capable of handling multiple narrow strips simultaneously while maintaining tight coil uniformity, which is essential for downstream winding or stamping processes.

Your cutting line specialists!

Factory in Japan

Factory in Japan

ADDRESS

487-3, Sanshincho, Chuoku, Hamamatsu, Shizuoka, Japan

Japan local market : +81 53-425-5331

Japan local market : +81 53-425-5331

Factory in China

Factory in China

ADDRESS

265 Yixian Road, Deqing, Zhejiang, China

Overseas market : +86 572-883-2016

Overseas market : +86 572-883-2016