The cut-to-length coil line is a high-performance processing system designed to transform coiled steel and aluminum sheets into precise flat sheets of various sizes. By uncoiling, straightening, measuring, and shearing, this machine ensures that every sheet produced meets strict dimensional accuracy standards. It is an essential piece of equipment for industries that require exact sheet specifications for subsequent fabrication, including automotive, shipbuilding, home appliances, and construction materials.

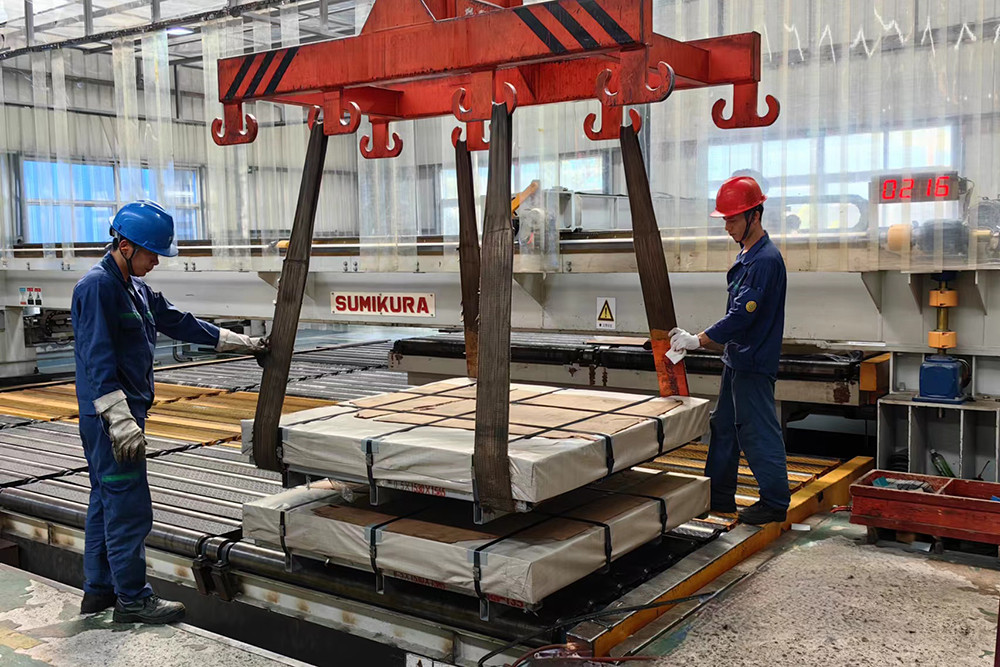

The primary function of the cut-to-length line is to uncoil large steel or aluminum coils and cut them into sheets of specific lengths. The process involves several stages: uncoiling, leveling, feeding, measuring, cutting, and stacking. This integrated system guarantees smooth operation from start to finish, minimizing material handling and improving productivity. The machine is capable of handling multiple materials such as High-Speed Steel (HSS), Cold Rolled Steel (CRS), Hot Rolled Steel (HRS), Stainless Steel (SS), and Aluminum, making it a versatile solution for different production needs. Typical uses include the preparation of sheet blanks for automotive panels, ship decks, appliance housings, roofing sheets, and structural parts.

This cut-to-length line offers robust performance with advanced automation. It supports sheet widths up to 2,500 mm and lengths up to 12,000 mm, allowing manufacturers to work with large-scale components efficiently. With a maximum coil weight of 35 tons, the machine is engineered to handle heavy-duty production requirements. Thickness capacity ranges from ultra-thin 0.2 mm sheets to robust 9.0 mm plates, ensuring adaptability across various applications. Operating speeds reach up to 80 meters per minute, with shear options including both stop shear and rotary shear modes for different production preferences. The leveling system provides high-precision flatness, while the measuring system ensures consistent length accuracy.

Material Compatibility: HSS, CRS, HRS, Stainless Steel, Aluminum

Width Capacity: Up to 2,500 mm

Length Capacity: Up to 12,000 mm

Maximum Coil Weight: 35 tons

Thickness Range: 0.2 mm – 9.0 mm

Operating Speed: 0–80 m/min

Shearing Options: Stop shear / Rotary shear

These specifications highlight the machine’s ability to meet demanding industrial standards, providing flexibility for small-batch precision work as well as mass production runs.

Your cutting line specialists!

Factory in Japan

Factory in Japan

ADDRESS

487-3, Sanshincho, Chuoku, Hamamatsu, Shizuoka, Japan

Japan local market : +81 53-425-5331

Japan local market : +81 53-425-5331

Factory in China

Factory in China

ADDRESS

265 Yixian Road, Deqing, Zhejiang, China

Overseas market : +86 572-883-2016

Overseas market : +86 572-883-2016