Electrical steel coil processing equipment is a specialized suite of machinery designed to handle high-grade electrical steel with the utmost precision. Electrical steel, also called silicon steel, is a critical material in transformers, motors, generators, and other electromagnetic applications, where even minor defects can affect efficiency and performance. These processing systems integrate multiple stages, including uncoiling, leveling, slitting, shearing, and recoiling, into a streamlined workflow. By automating these processes and using advanced control systems, manufacturers can achieve consistent quality, high productivity, and reduced material waste, ensuring that each coil meets stringent industry standards.

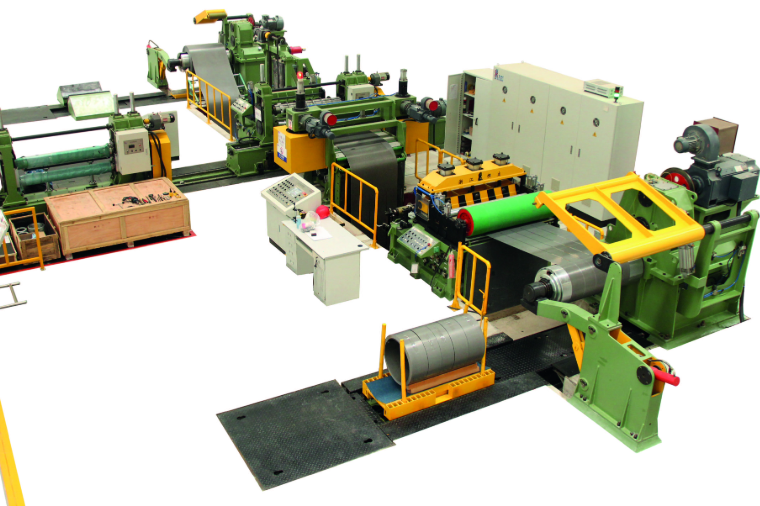

Electrical steel coil processing equipment is designed to cut, slit, and prepare coils for downstream applications while maintaining the integrity of the magnetic material. The equipment often includes uncoilers to feed the material, leveling machines to remove coil curvature, rotary or precision slitting systems for accurate strip widths, and recoilers for uniform rewinding. Some systems also feature tension control, edge-trimming, and inspection modules to detect defects in real time. These features make the equipment suitable for producing strips for transformer laminations, motor cores, stator laminations, and other electrical components. By ensuring smooth edges and precise thickness, this equipment maximizes material performance in applications where energy efficiency and low magnetic loss are critical.

A typical electrical steel coil processing line accommodates coil widths up to 2,500 mm and coil weights ranging from 10 to 35 tons, depending on the model and application. Material thickness can range from 0.23 mm to 0.5 mm for standard electrical steel, with some systems capable of handling ultra-thin high-grade laminations. Processing speeds vary between 80 to 150 meters per minute, depending on coil size and system configuration. Slitting systems are equipped with high-speed steel or alloy blades capable of producing narrow strips with burr-free edges, while recoilers ensure compact and uniform coil winding. Optional modules such as edge trimming, coil marking, and automatic stacking further enhance efficiency and product quality.

Operating electrical steel coil processing equipment requires careful setup and attention to detail. The coil must first be properly loaded onto the uncoiler and threaded through leveling, feeding, and slitting units. Operators then program the desired strip width, tension settings, and processing speed through the control system. Continuous monitoring of coil alignment, blade condition, and tension ensures consistent output quality. Regular maintenance, such as blade sharpening or replacement, lubrication of moving parts, and inspection of hydraulic or servo systems, is essential to prolong equipment life and maintain precision. Operators must also follow safety protocols rigorously when handling heavy coils and during operational adjustments.

Your cutting line specialists!

Factory in Japan

Factory in Japan

ADDRESS

487-3, Sanshincho, Chuoku, Hamamatsu, Shizuoka, Japan

Japan local market : +81 53-425-5331

Japan local market : +81 53-425-5331

Factory in China

Factory in China

ADDRESS

265 Yixian Road, Deqing, Zhejiang, China

Overseas market : +86 572-883-2016

Overseas market : +86 572-883-2016