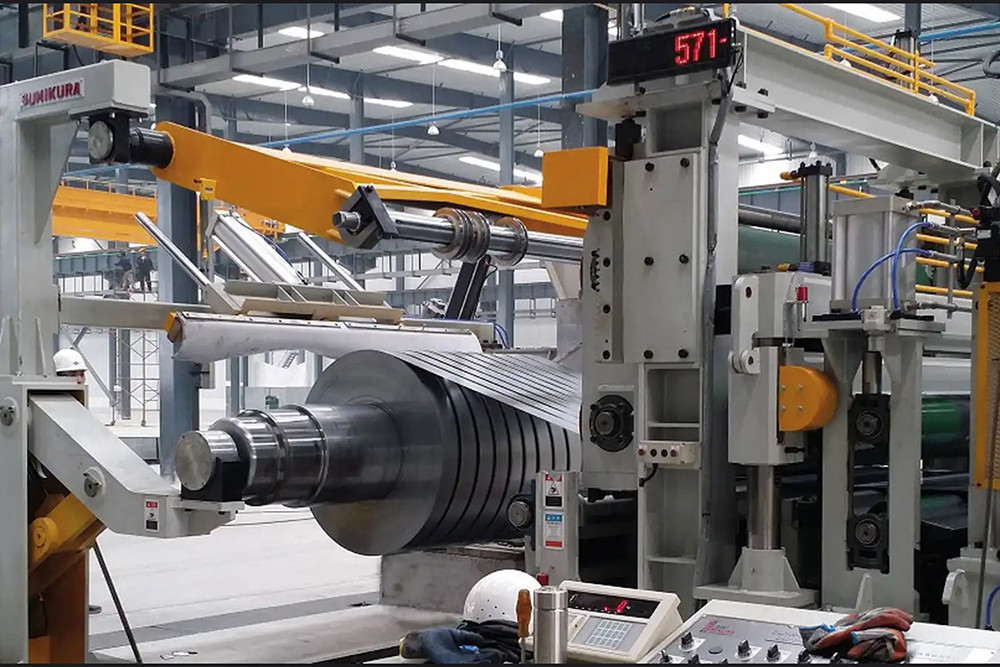

The Metal Steel Coil Cutting and Processing Line Machine is a modern solution for transforming coiled metal into high-precision sheets that meet the demands of today’s industrial production. Built with robust engineering and advanced control systems, this machine is capable of handling a wide variety of coil materials, including high-speed steel (HSS), cold rolled steel (CRS), hot rolled steel (HRS), stainless steel (SS), and aluminum. Its versatility makes it a valuable asset for companies seeking efficiency, accuracy, and flexibility in their coil processing operations.

One of the defining strengths of this processing line is its ability to accommodate a broad range of material sizes and properties. With a coil width capacity of up to 2,500 mm and maximum cutting lengths of 12,000 mm, it offers manufacturers the ability to produce both standard-sized and custom sheet dimensions with ease. The system is designed to process materials with thicknesses ranging from 0.2 mm for thin-gauge applications to 9.0 mm for heavy-duty industrial needs. This wide working range allows it to serve multiple sectors without requiring different machines for different jobs. In addition, its structural weight of 35 tons ensures stability, durability, and consistent performance even in demanding, high-output environments.

Speed and accuracy are central to efficient coil processing, and this machine delivers on both fronts. Capable of operating at speeds from 0 to 80 meters per minute, it balances high throughput with excellent dimensional accuracy, ensuring smooth workflows without sacrificing product quality. The inclusion of both stop shear and rotary shear options provides flexibility to handle diverse production requirements. The stop shear ensures clean and precise cuts for thicker materials or shorter runs, while the rotary shear is optimized for high-speed, continuous cutting, reducing downtime and maximizing efficiency.

For optimal performance, operators should ensure the coil material is properly aligned and securely mounted before initiating the cutting process. The machine’s advanced control systems allow operators to set exact parameters such as cut length, shear type, and processing speed. Regular inspection and maintenance of the leveling and shearing components are recommended to maintain accuracy and extend equipment lifespan. Operators should also monitor the material feed to avoid misalignment and ensure that safety protocols are followed during loading and unloading. With proper setup and routine servicing, the machine guarantees consistent output and reduced downtime.

Your cutting line specialists!

Factory in Japan

Factory in Japan

ADDRESS

487-3, Sanshincho, Chuoku, Hamamatsu, Shizuoka, Japan

Japan local market : +81 53-425-5331

Japan local market : +81 53-425-5331

Factory in China

Factory in China

ADDRESS

265 Yixian Road, Deqing, Zhejiang, China

Overseas market : +86 572-883-2016

Overseas market : +86 572-883-2016